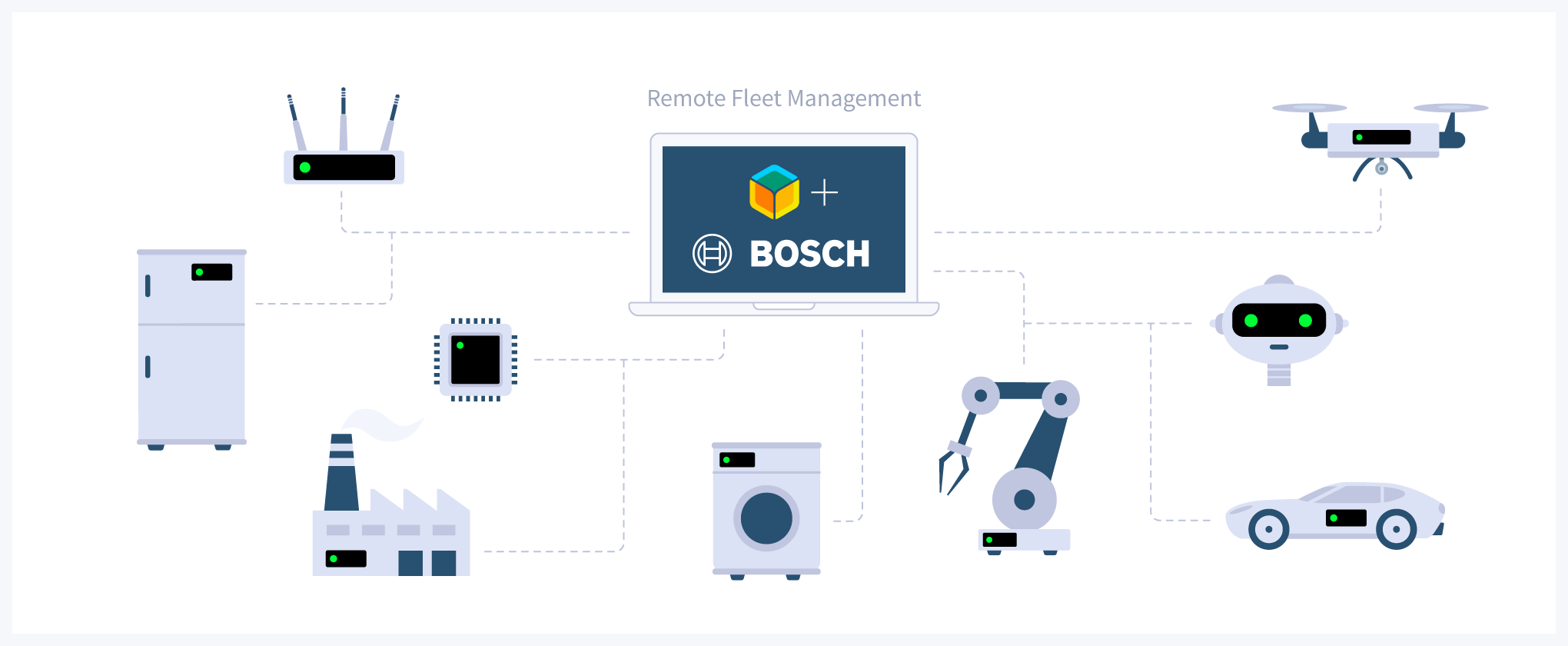

Learn how Bosch uses balena as part of their IoT fleet management and devops solutions.

Bosch is a world leading multinational engineering and electronics company who invests heavily in IoT; developing innovative solutions for smart homes, cities and manufacturing. Part of this research and development is looking for new business approaches in the context of industrial IoT, and in one such project, the team has developed a solution that is designed to monitor industrial hydraulic machinery.

This new edge device measures oil contamination in hydraulic systems throughout the machine, and provides a crucial early-warning system as to the condition of the entire hydraulic system so that downtimes can be prevented and availability increased.

How did Bosch learn about balena?

Bosch first discovered balena whilst organizing their Connected Experience Hackathon in 2017; one of the biggest IoT hackathons in Europe.

The team were struggling to provision devices with gateway software packaged in Docker containers for the hackathon participants. At the time, balena (Then known as ‘resin.io’) had just released a beta version of their (now live) multi-container feature, which solved the problem and allowed Bosch to run their hack challenge.

Integrating and using balena

Following the success of the event, Bosch has continued to use balena in a variety of ways. Stefan Rauch, a Software Engineer at Bosch took some time to tell us more about how, where and why their team chooses to use balena.

“Our services are developed in an agile, iterative approach, based on our customer’s feedback. We have to be able to deploy new features and updates to our installed base continuously and we embrace the idea of DevOps throughout our solution architecture, balena integrates perfectly into that approach.”

Bosch has built a continuous deployment pipeline that automatically pushes updates to their production and test fleets. The workflow is highly automated so developers don’t have to interact with balena directly to deploy new versions. For the ops part, they use the balena dashboard and balena-cli to remote access their installed base, allowing them to provide instant support to customers and partners.

Key benefits of using balena

When discussing the main benefits that balena delivers, Stefan told us “Being able to do software related tasks remotely, and managing and deploying to a large installed base are definitely the killer features of balena. This enables a very fast update cycle and therefore is a booster for the overall development speed of our services.”

“Deploying a new feature to an installed base that is distributed all over the world, just by doing a git push, is fascinating.”

In many industry projects, remote access to edge devices is not possible as they are deployed in isolated production networks, without internet access. Because of this, instant updates or immediate help for customers is not generally available. Using balena, the speed at which new features and updates are provided to Bosch customers helps to maximise product usability and reduce time frames between product upgrades and fixes.

Learn more

Check out balena for more information about our IoT solutions and to try the platform for yourself. You can also learn more about Bosch and their upcoming Connected Experience 2020 hackathon as well.